On a recent trip to China, I visited a wide range of companies and factories in the micromobility industry. Many had big names and bigger reputations, but one company surprised me as a silent, relatively unheard-of force behind many of the biggest e-bike companies in the world.

Meet Lishui, the company you’ve probably never heard of but have almost certainly used their products.

Inside the controller maker’s nondescript buildings are a series of laboratories and manufacturing halls where R&D and production occur. The company designs and builds controllers, essentially the brains of an electric bike, as well as other electronic components used in e-bikes and e-scooters.

To get your own look behind the curtain, follow on my tour in the video below. Then keep reading for all of the details!

As I explored the facility, it was impossible to miss the hundreds of electric bicycles parked pedal to pedal, mixed in and around the labs. Many were made by some of the biggest e-bike companies in the industry, both from North America and Europe.

Yes, the companies you’re thinking of right now, their bikes were there. So were the others. It was a veritable who’s who of e-bike movers and shakers. I can’t name names because Lishui doesn’t publicly announce who uses its products. And I’ve had to blur them all in the video and photos, both to protect their identities and because many of the bikes are new, unreleased models that arrive at Lishui early for testing with the company’s newest controllers and drive components.

But the numbers speak for themselves, with Lishui touting over 1,900 clients worldwide and selling over 13 million controllers to date. According to the company, 1 in 3 e-bikes in Europe are rolling around with a Lishui controller.

That success hasn’t come easily or quickly. The company has actually been around since 1979, getting its start making motor controllers for other industries. As the nascent e-bike industry came into fruition, Lishui switched over to purely micromobility controllers by 1997.

Unlike many other e-bike component makers, Lishui differentiates itself by doing all of its software and hardware development in-house. There’s no outsourcing here, they have their own team of nearly 60 engineers working on both the hardware and software side.

Many of those engineers have been with the company for over a decade, helping them retain the kind of talent and experience that tends to float to the top.

Lishui’s products cover three main markets: low-power 250W controllers for European e-bikes, higher-power 500W to 2,000W controllers for the North American market, and specialty controllers such as those with custom designs to fit inside battery cases and other specific use cases. For that last group, the company has developed deep connections with major battery makers over the past decade to help integrate its controllers directly into their battery cases.

And while many companies build controllers, Lishui further differentiates itself with a custom IoT suite, essentially making their controllers connected devices that allow companies and even end users to connect to the controllers over their phones and set or change parameters at will.

Along the way, Lishui has expanded its scope to include designing and building Bluetooth-enabled handlebar displays to take advantage of its sophisticated controllers further.

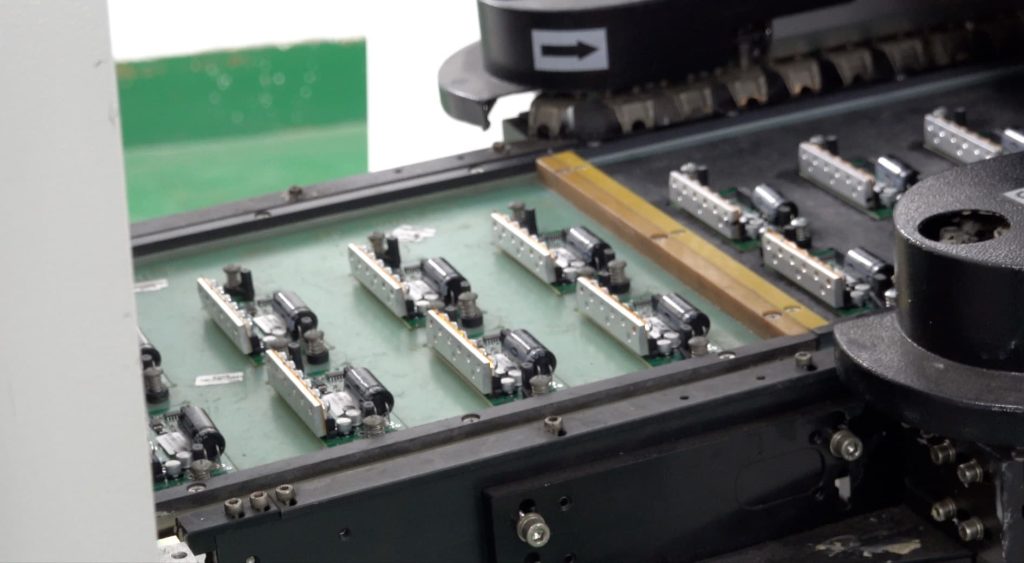

But designing such components is only half the battle. Lishui also handles in-house production of its high-tech components, using processes that are rooted in repetitive quality checks and spot tests to ensure all components are produced properly.

Much of the circuit board production occurs on-site here, with Lishui operating their own massive industrial soldering machines. A few hand soldering tasks are performed for larger components though, such as for the thicker power cables.

The circuit boards move to the mounting stages next, where they are enclosed in an extruded aluminum case and then filled with potting material to protect the electronics from water.

Next, the controllers are passed to the inspection stage, where they are connected to a testing rig that runs a series of 76 unique tests on the controllers. Each controller runs through these tests, ensuring that every product that leaves the factory has been electronically inspected for conformity and performance.

Interestingly, I even got to see a few aspects of the factory that I wasn’t expecting. For example, the company’s founder Mr. Xu, who it turns out has a major gardening hobby, has basically turned every bit of ground in the factory complex into sprawling gardens.

He’s got his own greenhouse for ornamentals but also large greenhouses for growing food throughout the winter months. Vines and trees dot the property, and a good-sized farm is tucked behind one of the warehouses, which is used to grow food used in the factory’s cafeteria for the workers.

In fact, Mr. Xu actually eats the same food in the same cafeteria as the workers, which was a refreshing sight to see. In other factories, I’ve seen VIP areas off to the side for the bosses to eat, and so it’s great to see that everyone from a new hire to the company founder all share the same lunch together.

Does it have any impact on the quality of the controllers? Maybe not. But the good morale that comes from walking among trees and flowers all day, as well as knowing that your boss doesn’t sit in an ivory tower, sure helps lead to a nicer working atmosphere. And so perhaps that does ultimately impact the quality of the work after all.

In the several hours I spent visiting Lishui, I went from not knowing much about this obscure powerhouse of a controller manufacturer to having a much deeper understanding of how they can supply millions of controllers to the world’s largest e-bike brands.

It all comes back to their depth of knowledge and experience in the field, their dedication to in-house development, and rigorous quality inspections.

And as an interesting final note, after seeing all of those secret e-bikes lining the halls and sides of the company test track, I now realize that I’ve had a few Lishui controllers sitting in my garage back home this whole time!

FTC: We use income earning auto affiliate links. More.