Toyota just got a $4.5 million boost from the US Department of Energy (DOE) to make EV batteries more sustainable.

The funding comes from ARPA-E’s CIRCULAR program, which focuses on creating a sustainable, domestic supply chain for EV batteries.

The project, led by Toyota Research Institute of North America (TRINA), aims to tackle one of the EV industry’s biggest challenges: What do we do with old batteries?

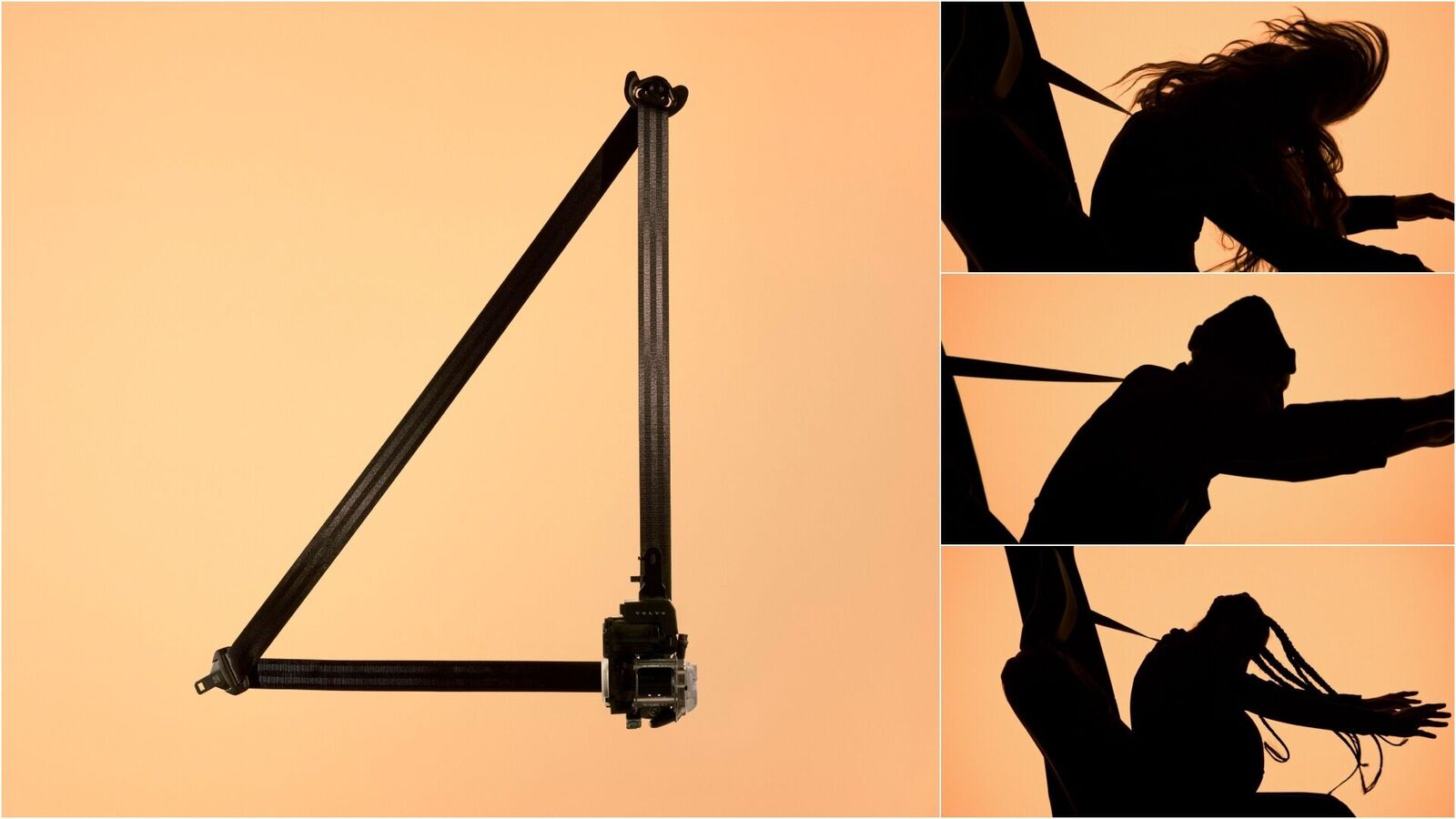

Right now, disassembling battery packs and figuring out which parts can be reused or recycled is a slow, manual, and costly process. Toyota, teaming up with Oak Ridge National Laboratory (ORNL), the National Renewable Energy Laboratory (NREL), and Baker Hughes’ Waygate Technologies, is working to change that.

Building the battery recycling center of the future

The project will focus on resolving the primary bottlenecks in the battery supply chain cycle, which are automating battery pack disassembly, data-driven battery classification, and addressing cell degradation. Think of it as a high-tech recycling center where every part of a used battery is carefully evaluated.

This approach could extend the life of valuable battery materials, reducing waste and the need to mine new resources. The ultimate goal? A blueprint for what Toyota calls a “3R facility of the future” – a place to reduce, reuse, and recycle batteries on an industrial scale.

Nik Singh, principal scientist at TRINA and principal investigator on this project, says the project could reshape how the industry approaches battery recycling:

This project and program will highlight avenues for everyone to rethink their approach to battery circularity, and help prioritize the extension of battery life, facilitate battery reuse, and reduce battery waste.

Tech innovations to close the loop

The team’s plan includes:

- Automated battery pack disassembly to speed up the recycling process.

- Advanced diagnostic tools to assess the condition of battery cells and modules.

- Refabrication methods to turn old cells into new energy systems.

The payoff? Batteries that are reused and refurbished first – recycling becomes the last resort.

Marm Dixit, leading ORNL’s contributions, points out the environmental benefits. “By extending the life of the battery components, we reduce their total emissions per mile. That’s a big deal for the role EVs can play in the energy transition,” Dixit said.

NREL’s role will involve cutting-edge tech like machine learning and imaging using nano computed tomography to analyze the health and lifespan of batteries quickly. Baker Hughes’ Waygate Technologies will bring its expertise in non-destructive testing with advanced imaging systems.

Toyota’s Battery Lifecycle Solutions (BLS) team plans to take these innovations from the lab to real-world applications. “By applying the innovations established from this project, we aim to create a framework that not only reduces battery waste but also enhances the circularity of our battery supply chain,” said Sarah Kennedy, BLS manager, who is leading the technology to market deployment.

Read more: EV batteries may last up to 40% longer than expected – Stanford

If you’re considering going solar, it’s always a good idea to get quotes from a few installers. To make sure you find a trusted, reliable solar installer near you that offers competitive pricing, check out EnergySage, a free service that makes it easy for you to go solar. It has hundreds of pre-vetted solar installers competing for your business, ensuring you get high-quality solutions and save 20-30% compared to going it alone. Plus, it’s free to use, and you won’t get sales calls until you select an installer and share your phone number with them.

Your personalized solar quotes are easy to compare online and you’ll get access to unbiased Energy Advisors to help you every step of the way. Get started here.

FTC: We use income earning auto affiliate links. More.