NETZSCH, a developer of positive displacement pumps, has demonstrated its fluid pumping solutions for lithium battery manufacturing.

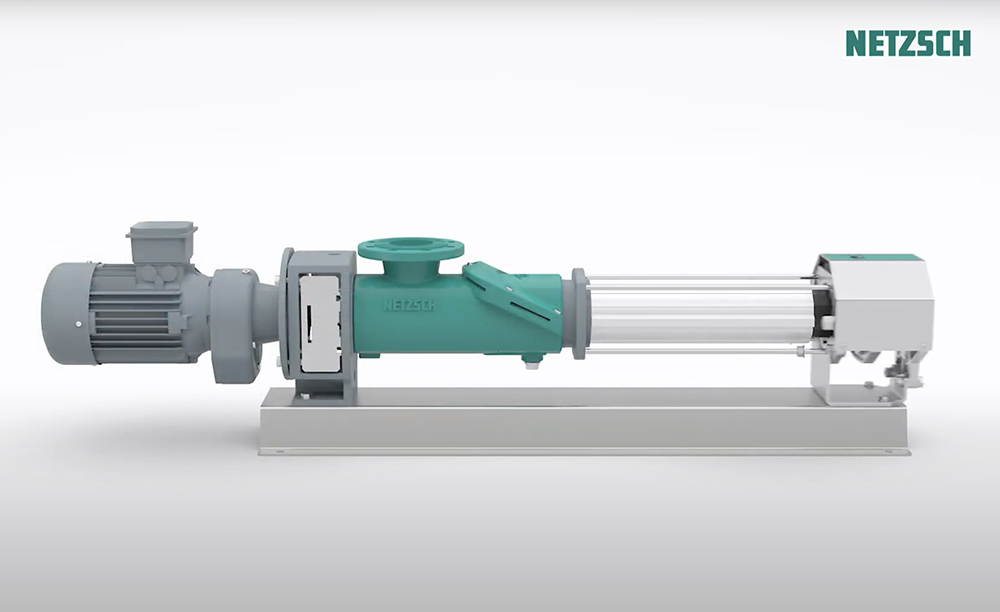

NETZSCH’s NEMO progressive cavity pumps are positive displacement pumps that have a rotating rotor and stationary stator. Rotors are round-threaded screws with one side hinged or elastically attached. The output axial position oscillates. Elastic hollow stators have the same pitch length as rotors, leaving conveying spaces between the stator and rotor that move continuously from inlet to outlet. NEMO pumps can measure or transfer ceramic slurries, electrolytes, adhesives, resins and other battery process fluids, including aggressive solvents.

The PERIPRO peristaltic pumps are also positive displacement pumps, which have heavy-duty, precision machined elastomer hoses for +/-1% flow accuracy and rollers for longer service life. The hose is their only wear part. External mechanical deformation forces the product through the hose. Rollers clamp the hose to the pump head housing, a rotor turns the rollers, and the rotation moves the pinch-off point along the hose, propelling the pumped product. The hose’s elasticity creates the suction vacuum, and the pump’s design makes it insensitive to dry-running. These pumps can handle complex slurry fluids like abrasive, corrosive, viscous and shear-sensitive, delicate products that only touch the elastomer hose.

The seal-less PERIPRO peristaltic pumps are ideal for lithium battery manufacturing because no hazardous vapors or emissions can escape, according to the company.

Source: NETZSCH