Battery venting systems are safety features that quickly reduce the pressure inside a segment of an EV battery when a fault occurs.

KACO, a German manufacturer of high-precision sealing solutions for the automotive industry, has launched a new generation of battery venting systems, which it says can greatly improve the safety and performance of battery packs.

KACO’s next-gen battery venting solution is a reversible, metallic quick venting system that is equipped with a valve circuit, and includes four different functions:

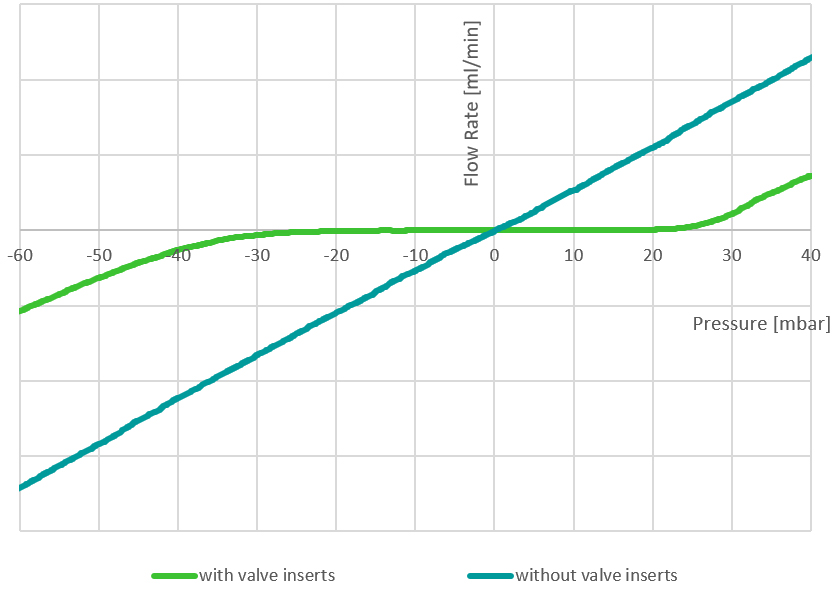

- No ventilation or venting takes place between -20 mbar and +15 mbar (adjustable).

- Ventilation (through a membrane) with a flow rate of ≥ 400 ml/min @ -50 mbar. Once the release pressure is reached due to an increase in pressure inside the battery housing, the venting piston allows air to escape, and the pressure is equalized. After venting, a spring returns the piston to its original position.

- Venting (through a membrane) with a flow rate of ≥ 600 ml/min @ +50 mbar. Once the necessary negative pressure is reached, the ventilation piston changes its position and air can flow in.

- Emergency venting with a flow of ≥ 100 l/s @ +200 mbar. Once the trigger pressure for emergency venting is reached, the piston is suddenly pushed upwards, releasing the entire cross-section for emergency venting.

This system features IP 68 and IPX9K protection; a flammability rating of UL94-V0; water resistance of over 250 mbar for 30 minutes; adjustable opening pressure; leakage of ≤ 1 ml/min @ -15 mbar and an operating temperature range of -40° to 80° C.

Source: KACO