Adhesive and sealant specialist Henkel has added three new products to its portfolio of dedicated potting adhesives, each tailored to meet specific challenges.

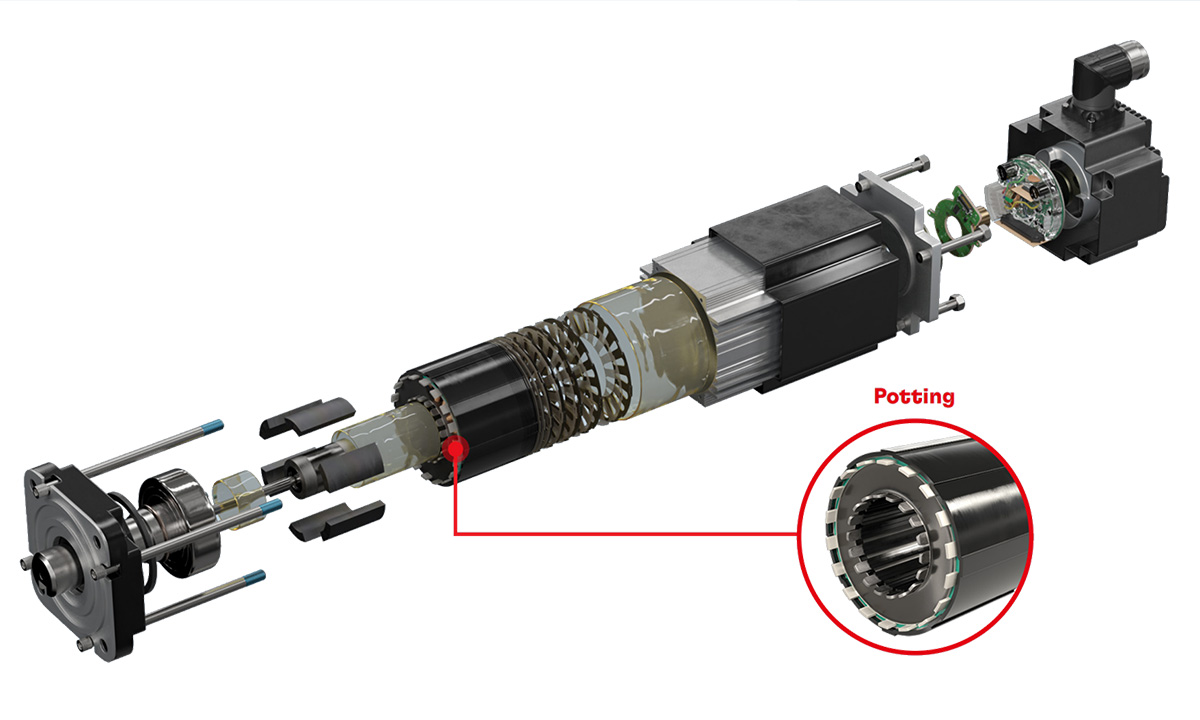

Potting of sensitive electronic components such as ECU connectors, sensors and e-motors protects them from moisture and exposure to common automotive fluids. Henkel’s new potting products are designed to enable more efficient encapsulation and protection of components. They’re engineered for seamless integration into existing manufacturing processes and optimal compatibility with materials used in automotive applications.

Loctite SI 5035 is a one-part silicone potting sealant that provides corrosion-free potting for sensitive components such as ECU connectors. As a flowable sealant, it offers the advantage of deep light cure capability, ultraviolet and visible, combined with a secondary moisture cure mechanism for shadow curing. Loctite SI 5035 forms a medium-strength, flexible rubber sealant that can withstand high-pressure testing immediately after UV curing. The UV cure system eliminates the need for energy-intensive ovens common with typical heat cure systems. The fast depth of cure is designed to reduce the need for staging parts usually required with standard RTV silicones, reducing process footprint on the plant floor.

Loctite AA 5832 is a dual-cure (UV/moisture) polyacrylate potting sealant designed for high performance in sealing against automatic transmission fluids and oil. This one-component, low-viscosity material is used for potting and sealing components such as ECU connectors, mechatronics and ADAS components, increasing their reliability in harsh automotive environments. Loctite AA 5832 is cured via UV light, which enables lower energy consumption.

Loctite PE 8086 AB is a thermally-conductive potting material specially designed for encapsulation and protection of components such as motor stators, actuators, transformer coils and transmission actuators from thermal shock. This two-component epoxy material offers high thermal conductivity, low mixed viscosity for easy processing, excellent electrical insulation at high and room temperatures, and automatic transmission fluid (ATF) oil resistance. Loctite PE 8086 AB maintains optimal operating temperatures to ensure peak performance, while protecting components from environmental factors, contaminants, and mechanical stress. As a solvent-free product that produces no VOCs during the curing process, it enables more sustainable manufacturing. It also uses less abrasive material, thereby reducing equipment wear.

“As a leader in adhesives, sealants, and functional coatings for the automotive industry, Henkel is meeting the evolving challenges of automotive electronics with a comprehensive range of potting solutions,” says Arthur Ackermann, Business Development Manager Auto Electronics North America at Henkel. “Utilizing our strong expertise and innovation capabilities, these new products have been developed in collaboration with our customers and partners to surpass industry expectations. They not only enable high efficiency, high-accuracy manufacturing but also ensure the durability, longevity and dependability of components over the vehicle’s lifecycle.”

Source: Henkel