New Delhi: As the electric play in the commercial vehicle (CV) industry is gaining momentum, a duo of Gurugarm-based engineers is building Planet Electric, a startup which is manufacturing four-wheeled cargo electric vehicles (EV), but with a cost effective solution relying on lightweighting technology with composite materials for its chassis, body and the cargo box.

A brainchild of Gagan Agrawal (33) and Prakhar Agarwal (35), the company was incorporated in 2021 to take on the conventional players including Tata ACE, Mahindra Bada Dost, amongst others. While it still has a long way to go before it turns its dreams into reality, the innovation materials engineering for lightweighting of EVs cannot be ignored.

“We knew that composite materials are already in use in aviation and aerospace because aluminium fuselages were replaced by composite fuselages and fuel efficiency had gone up by 25%. We knew that cooling towers and multiple other things were being built, except motor vehicles,” Gagan Agrawal, Co-Founder & CEO, Planet Electric, told ETAuto.

After completing his B.Tech degree, Agrawal got into Indian Space Research Organisation (ISRO) as part of a scholarship. While he worked there for just 3 years, his entrepreneur brain had big plans. Prakhar Aggarwal, Co-Founder & CTO was at ISRO for 10 years, specifically working in building rocket and spacecraft structures with composite materials.

Both the aerospace engineers gained confidence in composite materials when they were working on a rocket project during their college days. However, they realized in time that aerospace processes could not be applied on motor vehicles without them being pricey, as the latter is typically built in hundreds of 1000s, and you can accept certain amounts of defects on a six sigma criteria. They are built at 300%- 400% margin and involve a different class of material.

“If this had to ever work in Indian conditions, we had to figure out a way on how to make it affordable and lightweight. It took us a year to get this on top by looking at various processes, including compression moulding, thermoforming, and pultrusion,” Agrawal recalled.

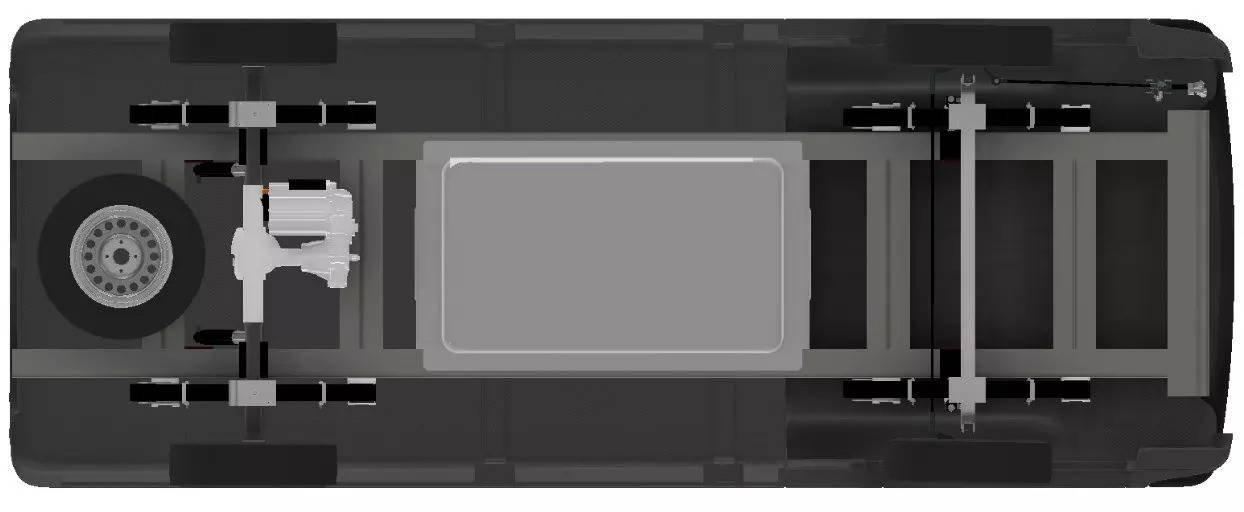

Working on the E-LCV project for three years now, the startup will showcase its Foak lightweight chassis made with high strength composite materials. The company claims that the new chassis is 67% lighter than the competition and will allow for up to 50% battery capacity reduction leading to superior cost economics.

Market entry by November

The prototype of the electric light commercial vehicle (E-LCV) will be out in April this year. The homologation process is slated to begin in June, and end by September. Post this, the company is planning to launch the model by October-end or November, during the festive season in the country.

Agrawal shares that the vehicle is built on a 320V architecture platform. The vehicle architecture involves 92V system, 21.4 kWh battery pack, 27 kW motor, rated payload of 600 kg, and the certification range of 154 km. It will come with two options for battery packs, another one being 15kWh with 165 km certification range and 750 kg rated payload.

The E-LCV gets an AC cabin, a screen and weight sensors in the cargo box so the driver is aware how much range is possible as the range is directly proportional to how much weight is there on the vehicle, especially for logistics applications.

While the acquisition cost was a big factor in play, Agrawal is still cautious as because of the added cost of new materials, “we have to take a hit of about INR 70,000 on the product in the short term, which will pay off very well in the long term”.

Road Ahead

Aiming to sell 1500 vehicles by March 2025, it is looking to generate an annual revenue of USD 20 million to 30 million. The vehicles could be priced from INR 9 lakh, going up to INR 10.5 lakh.

Six months ago, Planet Earth raised INR 250,000 in its pre-seed round. In the next three months, the company is looking to raise USD 13 million which will largely be spent in building the production facility and its go-to-market strategy. For the production facility, the company has finalized a rented space in Manesar.

“Once the funding round is complete, we should be able to start the production by July. It will push us to bring up a production facility of 4,000 units per annum and get us access to other markets,” Aggarwal said.

Planet Electric aims to make its foray in exports markets including Middle east, Indonesia, East Africa. It is also in talks with a few players in Dubai and Saudi Arabia for putting up a manufacturing facility as “export units will most likely be manufactured outside India because the scope of domestic market itself is quite large here”.