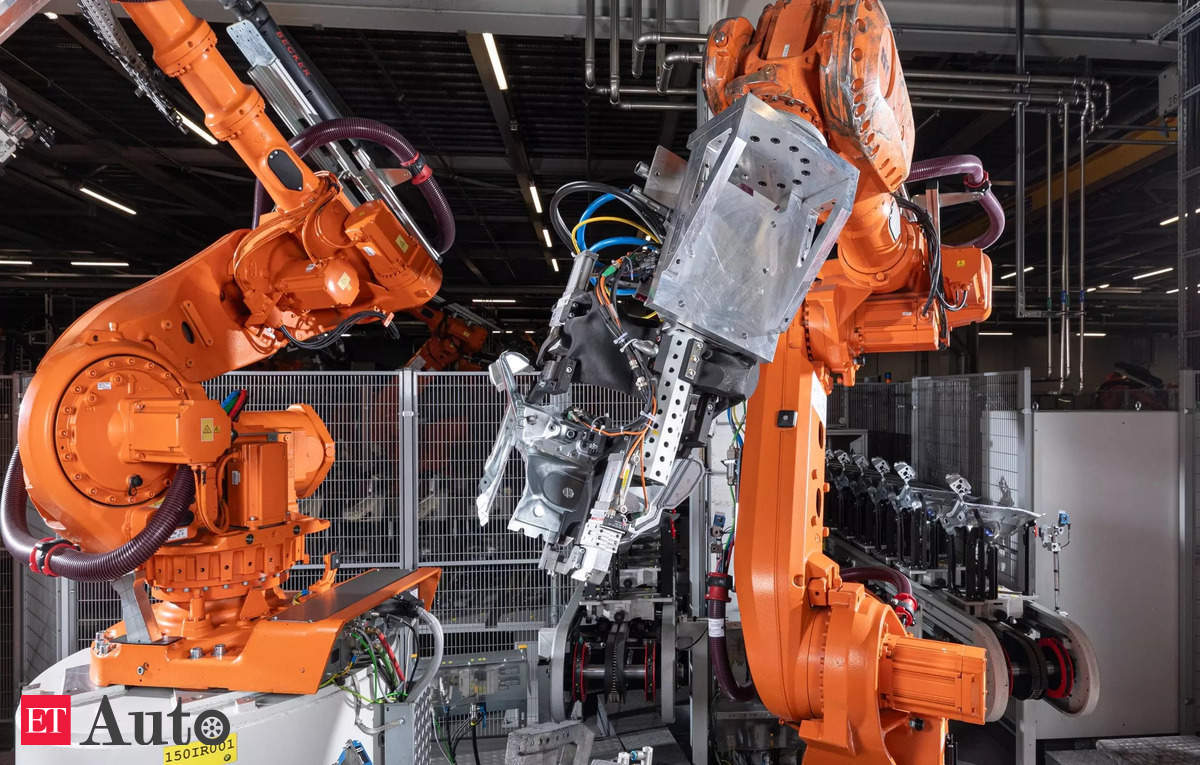

New Delhi: BMW Group has advanced its manufacturing process by integrating custom 3D-printed gripper robots at its Munich plant, significantly boosting efficiency on production lines, including those assembling the BMW i4. These innovative bionic grippers are 30% lighter than traditional models, handling loads up to 110 kilograms, which increases load capacity and reduces carbon emissions.

The new grippers are also being used in other BMW plants, utilizing selective laser sintering and large-scale printing for tasks such as managing CFRP roofs on BMW M GmbH models. In 2023, BMW’s focus on additive manufacturing resulted in over 400,000 parts produced using this technology.

Jens Ertel, Head of BMW Additive Manufacturing, emphasized the benefits of this approach, including quicker production of specialized tools and robots, cost reduction on production lines, and overall effectiveness. This strategy underscores BMW’s commitment to leveraging additive manufacturing for sustainable and high-performance automotive solutions globally.