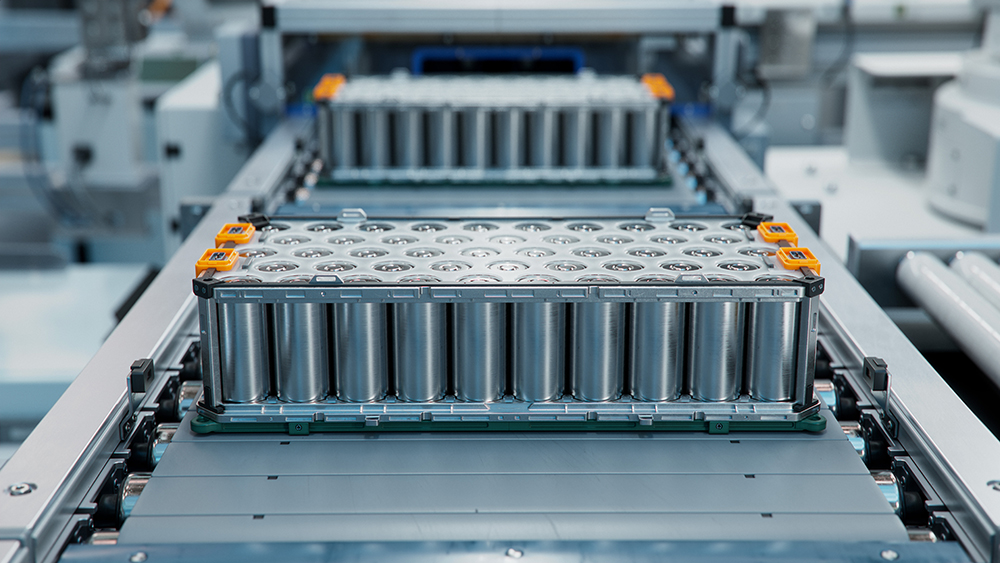

The need to quickly increase EV battery testing capacity is making validation labs harder to manage and forcing engineering teams to explore ways to sustainably scale up their test lab operations. Battery cyclers that are flexible, open, and connected are critical to achieve the scale needed in modern battery validation labs.

Join this webinar, presented by NI—Now Part of Emerson, to take a look into the world of power electronics for battery testing.

Other sessions at our Spring Virtual Conference include:

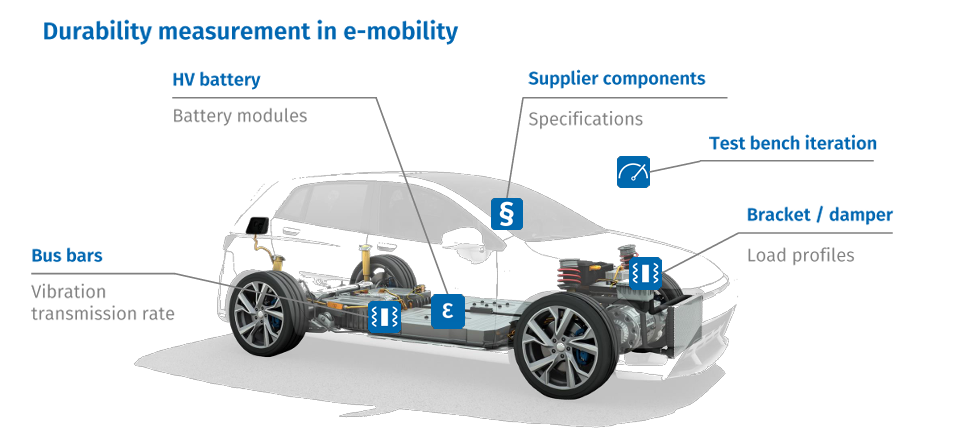

Durability Measurement Technology For xEV Testing

Testing of durability poses great challenges for the measurement equipment to be used, especially in the high-voltage environment. For example, the so-called “swelling” is to be investigated on HV battery cells. For this purpose, strain gauges are primarily used whose output signals, some of which are very small, must be recorded precisely, reliably and safely at a high voltage potential.

- Which critical points in EVs typically have to be examined for their durability?

- How can the signals of bridge-based sensors such as strain gauges be acquired in a HV-safe manner?

- What challenges arise in particular with strain gauge measurements at HV potential and how can they be solved?

Join this webinar, presented by CSM, to learn more.

Metal Processing Solutions For BEV Bodies And Components

Moving toward an electric future in the automotive industry requires component suppliers and automotive manufacturers to meet an ever-growing list of must-haves.

- Production must be efficient and streamlined to meet burgeoning demand

- Performance must meet the highest standards to ensure safety and durability across rigorous conditions

- Sustainability must be an integral part of both the production process and the on-the-road experience

- Cost must be reduced while achieving all of the above

Join this webinar, presented by Henkel, to explore how metal processing solutions, including casting lubricants, cleaners and surface treatment, enable end-to-end success of battery electric vehicles—from molten metal to final component.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live on April 15-18, 2024, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.