Indian-manufactured electric vehicles (EVs) are often considered lower in quality compared to their European or other global counterparts due to several key factors. Here’s a breakdown of why this gap exists:

1. Cost-Driven Market vs. Quality-Driven Market

- India is a price-sensitive market, where affordability takes priority over premium features and build quality.

- Europe & Other Developed Markets focus more on performance, safety, and durability, even if it increases the vehicle’s price.

- Indian manufacturers often cut costs on materials, safety features, and battery technology to keep EVs affordable.

2. Inferior Battery Technology & Thermal Management

- Most Indian EVs use less advanced battery cells sourced from China rather than premium LG Chem, Panasonic, or CATL cells used in European models.

- Poor thermal management systems increase the risk of overheating and battery degradation.

- European and global brands use better battery cooling systems (liquid-cooled), whereas many Indian EVs rely on air cooling, which is less efficient.

3. Lower Safety Standards & Testing

- Europe has strict crash test regulations (NCAP, Euro NCAP), which force manufacturers to build safer cars with features like multiple airbags, stability control, and reinforced structures.

- India’s safety regulations are improving, but still allow less stringent crash tests, leading to weaker body structures and lower safety ratings.

- Many Indian EVs are not tested under Global NCAP standards, or score poorly when tested.

4. Limited R&D and Innovation

- European and American companies invest billions in R&D for better battery chemistry, software, and AI-powered driving systems.

- Indian EV manufacturers lack the same level of funding and expertise, leading to slower innovation.

- Indian EVs often use older-generation technology that has been phased out in Western markets.

5. Weak Charging Infrastructure & Software Optimization

- European and Chinese EVs are designed for advanced fast-charging networks (800V architecture, ultra-fast DC charging).

- Indian EVs are mostly built for slow AC charging, with limited fast-charging support.

- Software-related bugs and glitches (e.g., Ola S1 Pro’s sudden shutdowns) indicate poor software optimization.

6. Material Quality & Manufacturing Precision

- European manufacturers use higher-grade materials for interiors, exteriors, and components.

- Indian EVs often use cheaper plastic, lower-quality steel, and basic components to reduce production costs.

- The fit and finish of Indian EVs is often inconsistent, leading to complaints about build quality.

7. Supply Chain & Component Sourcing

- India still relies heavily on imported parts (batteries, motors, electronics) from China, which affects quality control.

- European and American manufacturers produce high-quality components in-house or use trusted suppliers with strict quality checks.

8. Lack of Long-Term Testing & Durability

- European and American brands test EVs in extreme climates (cold, heat, rain) for years before launching.

- Many Indian EVs are rushed to market without proper durability testing, leading to battery failures, software issues, and performance degradation over time.

Conclusion: The Gap is Closing

Indian EVs are improving, with brands like Tata, Mahindra, and MG making progress in safety and performance. However, cost-cutting, weaker regulations, and lower-quality materials still hold them back compared to European and American models. With better R&D, stricter safety norms, and local battery production, the quality gap will reduce in the coming years.

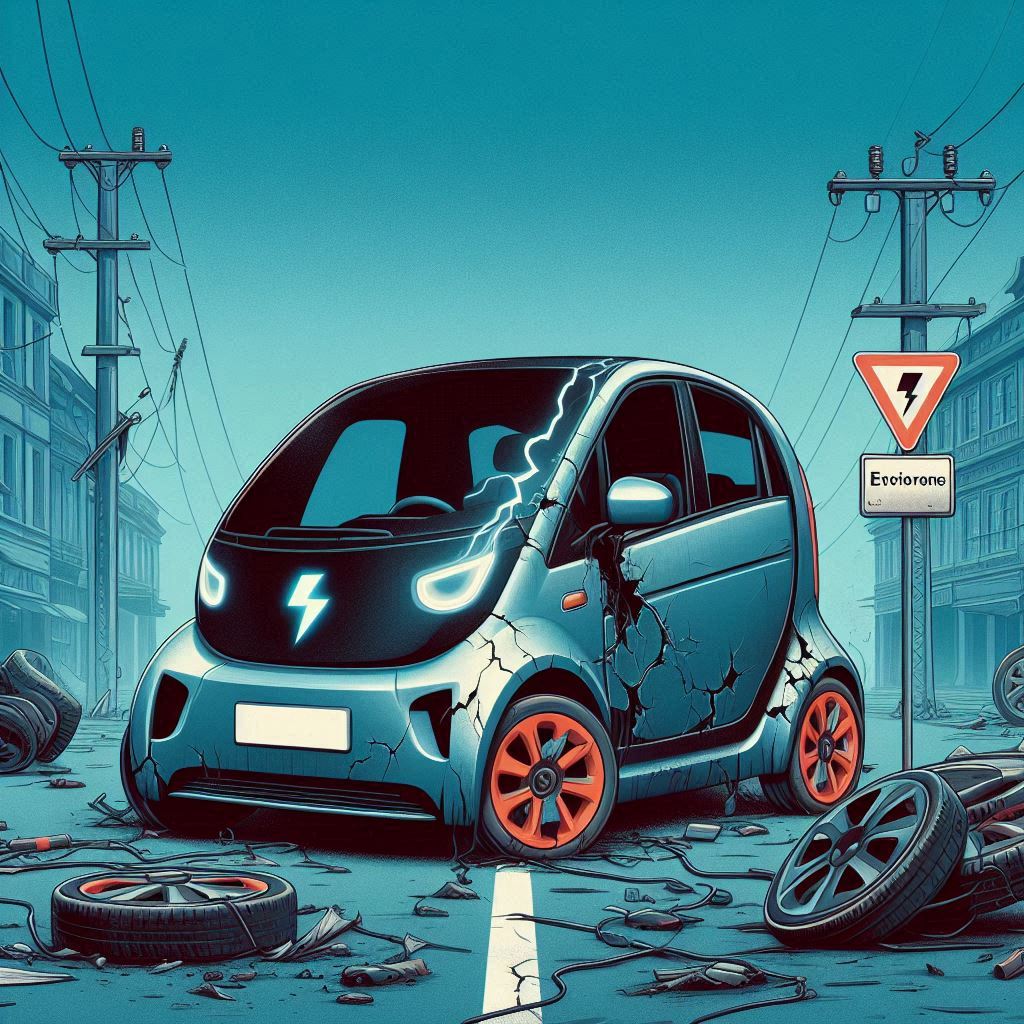

Recent failures of indian evs

In recent years, India’s electric vehicle (EV) industry has faced several challenges, leading to notable failures and setbacks. Key issues include:

1. Battery Fires and Safety Concerns

There have been multiple incidents of electric scooters catching fire, raising serious safety concerns among consumers. For instance, in Pune, an e-scooter caught fire, and a similar incident in Vellore, Tamil Nadu, resulted in two fatalities. These events have been attributed to factors such as poor battery management systems, substandard battery cells, and inadequate thermal management. Experts suggest that the haste to launch products without thorough testing, especially in India’s hot climate, has contributed to these failures.

2. High Volume of Customer Complaints

Ola Electric, a prominent e-scooter manufacturer, received over 10,000 customer complaints within a year. Issues reported include delayed services, unsatisfactory responses, inaccurate invoices, and unprofessional conduct. The Central Consumer Protection Authority issued a notice to Ola, highlighting the repeated nature of these complaints and the need for regulatory intervention.

3. Market Challenges and Low Adoption Rates

Despite government incentives, electric cars hold just a 2% market share in India. Challenges such as inadequate battery life, insufficient charging infrastructure, and theft-prone chargers deter buyers, creating a chicken-and-egg scenario that impedes EV adoption.

4. Early EV Model Failures

India’s first electric car, the REVAi (also known as G-Wiz), faced significant criticism for being underpowered, unsafe, and aesthetically unappealing. Produced between 2001 and 2012, it struggled with low sales and was eventually discontinued. The REVAi’s shortcomings highlighted the challenges of introducing EVs without adequate infrastructure and consumer acceptance.

These incidents underscore the importance of rigorous testing, quality assurance, and robust after-sales support in the Indian EV industry. Addressing these challenges is crucial for building consumer trust and ensuring the long-term success of electric vehicles in India.

Indian EV manufacturers with major failures

Here are some Indian EV manufacturers with major failures and controversies:

1. Ola Electric 🚨 (Most Controversial)

Issues:

- Frequent battery fires & safety concerns (Incidents of scooters catching fire, leading to recalls)

- Poor customer service (Over 10,000 complaints, leading to a government notice)

- Faulty software & sudden breakdowns (Users report scooters shutting down mid-ride)

- Misleading range claims (Real-world performance much lower than advertised)

- Production & employee layoffs (Recently laid off 500 employees)

🔴 Verdict: Rushed production and aggressive marketing, but poor execution and after-sales service.

👉 Sources: Reuters Report on Ola Complaints

While it’s difficult to label any one company as the absolute worst EV manufacturer in India, several companies have faced serious issues, including safety concerns, poor build quality, customer complaints, and service failures. Here are some Indian EV manufacturers with major failures and controversies:

1. Ola Electric 🚨 (Most Controversial)

Issues:

- Frequent battery fires & safety concerns (Incidents of scooters catching fire, leading to recalls)

- Poor customer service (Over 10,000 complaints, leading to a government notice)

- Faulty software & sudden breakdowns (Users report scooters shutting down mid-ride)

- Misleading range claims (Real-world performance much lower than advertised)

- Production & employee layoffs (Recently laid off 500 employees)

🔴 Verdict: Rushed production and aggressive marketing, but poor execution and after-sales service.

👉 Sources: Reuters Report on Ola Complaints

2. Hero Electric ⚡ (Legacy Brand, But Struggling)

Issues:

- Low-quality build & poor battery management

- Slow charging & range anxiety (Real-world mileage significantly lower)

- Lack of innovation (Outdated tech compared to Ather & Ola)

- Service network issues (Complaints about poor response times)

🔴 Verdict: One of the oldest EV players but lagging behind in technology and reliability.

3. Ampere Electric (by Greaves) 🛵 (Budget EVs, But Unreliable)

Issues:

- Cheap build quality (Reports of parts breaking easily)

- Limited range & slow speed

- Frequent battery issues (Many customers report battery failures within months)

- Lack of proper service centers

🔴 Verdict: Very budget-friendly but not built for long-term reliability.

4. Revolt Motors 🏍️ (Electric Motorcycles with Issues)

Issues:

- Repeated delays in deliveries

- Limited availability of spare parts

- Battery & motor durability concerns

- Poor resale value

🔴 Verdict: Good concept (electric bikes), but poor execution and customer experience.

Who is Doing Better? ✅

Among Indian manufacturers, Tata Motors and Ather Energy are considered more reliable.

- Tata Nexon EV & Ather 450X have been better tested, safer, and more reliable than competitors.

- Mahindra EVs (XUV400) also show promise but need better charging infrastructure.